Heartland Certified Pre-owned Equipment Refurbishing Process

Heartland Certified Pre-owned Equipment Refurbishing Process Heartland Medical Sales and Services LLC became incorporated in 1998. As anesthesia system specialist, the founding principals had 19 to 30 years experience maintaining, repairing and refurbishing all models of anesthetic equipment being marketed in the United States. The company was built on providing great products at a great value with unmatched support. Today, Heartland Medical Sales and Services LLC has grown from being a Midwest Regional Anesthesia Specialty Service Company with the largest facility dedicated to refurbishing anesthesia systems to one of the largest medical equipment providers in the world. Heartland Medical Sales and Services LLC offers a wide range of medical products. With its core values in mind, these products and services are still offered at a great value with continued unmatched support. The company continues to focus their expertise on the operating room with sales of surgical tables, surgical lights, patient monitors, ESUs and other capital goods related to the OR.

Attributes of a True Professional Re-Marketer: Inventory on Demand: Heartland Medical Sales and Services LLC operates from a 12,000 sq ft facility. Inventory is acquired through various means. Trade in equipment as a result of new sales transactions is the most likely scenario. The company works closely with hospitals and surgical centers in purchasing the very best surplus equipment by offering the most competitive bids. Heartland Medical Sales and Services LLC also created strategic alliances with major manufacturers and distributors to secure the products necessary to offer a complete solution for our customers’ needs. In most cases the equipment has been maintained by Heartland Medical’s service personnel during its entire life. This business model provides the best equipment, at the best value with on demand availability.

Receiving/Incoming QC: Incoming equipment is received and tagged. The key features are logged into our database for later customer queries. The units are inspected and graded based on cosmetic appearance. An operational and biomedical test is conducted to evaluate the equipments current condition. A record of the results is logged. No work begins until an order is received for the unit.

Production Scheduling: Once the order is received the units are tagged with new owner’s information, custom request, and projected ship date and order criteria. The units are moved to the preparation area for the refurbishing process to begin.

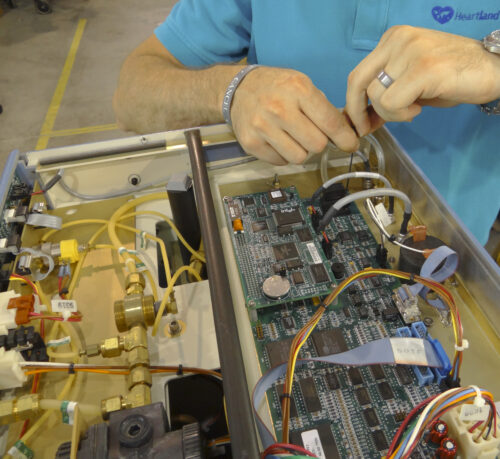

Cosmetic Refurbishing: The equipment is dismantled down to the basic frame/cabinet and is cosmetically renewed with sanding, polishing and painting with medical grade paint. This process takes approximately one week to take from basic component back up to a completed unit.

Technical/Electronic/Pneumatic/Mechanical Refurbishing: Our certified technicians analyze each sub-assembly for wear and proper function. Worn components are replaced with OEM components to original manufacturer’s specifications as when the unit was sold new. Any part not functioning to manufacturer spec is replaced in the same manner. The technicians will install all periodic parts kits; six month, one year, two year and three year maintenance kits to bring the equipment to the highest level. Rubber goods are replaced, tubing, rolling diaphragms, peep diaphragms, APL diaphragms, canisters and gaskets, O2 sensors are replaced. Software upgrades are installed to latest level where applicable.

Certification: All buyers of pre-owned equipment should demand this level of certification from all vendors to reduce risk for yourself and be assured the company you are dealing with is reputable. At Heartland Medical Sales and Services LLC, the equipment is tested for proper function to manufacturer specs (as when sold new) with certified test equipment by senior certified technicians. Documents are supplied to the customer and maintained on file at Heartland Medical.

Delivery: The delicate sub components are wrapped individually and packaged within the unit. External areas are bubble wrapped; shrink wrapped and can be blanket wrapped and shipped via moving van or crated and vacuum packed for overseas shipment. Smaller items such as monitors and defibrillators are plastic wrapped, bubble wrapped and boxed with injection foam protecting the items. Heartland Medical will aid in the shipping process by offering our own trucks or arrange freight and insurance per your guidance.

Installation: This service is available for those wishing Heartland Medical to assist in the install and training of staff members. The equipment is certified and inspected prior to packaging however; we strongly suggest that each piece of equipment be inspected by a qualified technician prior to being put into operation to verify there was no damage during transit. Our technicians can be on-site and perform the necessary inspections and re-certify the equipment to be patient ready.

Terms: Many companies take the order and the payment before equipment arrives at your dock. The installation becomes your burden. When deficiencies are found; the selling company usually balks at retribution. Let us be responsible from beginning to end in the process. Heartland Medical Sales and Services LLC has a variety of payment terms available to aid you in your financing and our technicians stand ready to assist you with every step in the installation process.